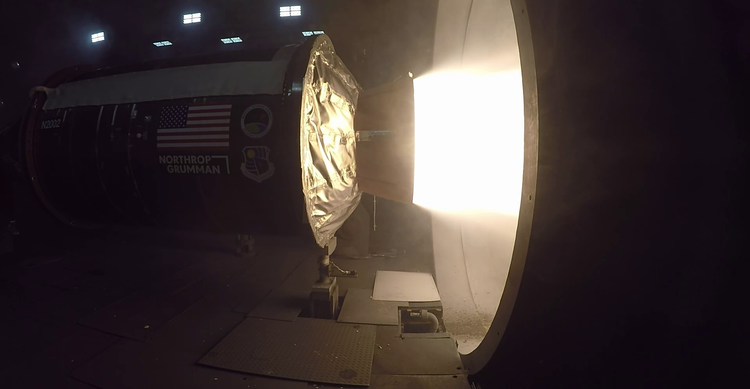

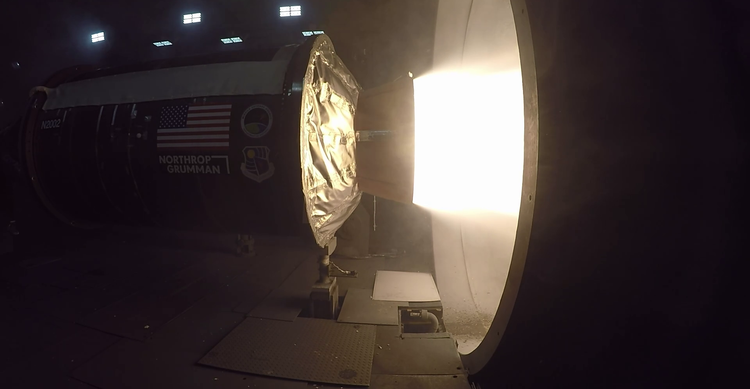

ARNOLD AIR FORCE BASE, Tenn. – Aug. 8, 2024 – Northrop Grumman Corporation’s (NYSE: NOC) digitally designed and manufactured large solid rocket motor successfully completed a static fire test at U.S. Air Force Arnold Engineering Development Complex.

- All test objectives were met during the event with performance data anchoring the digital model, confirming the motor’s performance and demonstrating the company’s ability to successfully build to design requirements using a digital environment.

- In addition to advanced model-based systems engineering (MBSE) used to design the high-performance second stage motor, a digital environment was also applied to the facilities and tools to manufacture the propulsion system.

- MBSE enables teams to extract data that enhances manufacturing processes and design evaluation, improves response to market demands, accelerates the implementation of process improvements and augments the company’s production capabilities.

Expert:

Jim Kalberer, vice president, propulsion systems: “We are using digital solutions across our business to produce solid rocket motors with speed, which is transforming how we design, test and manufacture the next generation of systems. The company’s propulsion business uses this level of engineering to deploy an advanced approach for newly developed rocket motors that are pushing model-based tools further than ever before.”

Details:

The test event was the company’s second successful static firing of a fully digitally designed large solid rocket motor. The first was the Common 50 High-Performance (C50HP) upper stage motor that can be adapted to support final stages of propulsion in the region outside of Earth’s atmosphere. The second stage motor is optimized for high-altitude flight and provides the required boost to transition payloads out of the atmosphere and into space.

With nearly 100,000 employees and over 30 million square feet of manufacturing space – more than 500 football fields – Northrop Grumman has the capacity, scale, and agility to drive innovation at unprecedented speeds. The company’s manufacturing approaches do more than just produce; they accelerate and enhance the entire process from design and development to production and testing. Northrop Grumman has invested in U.S. infrastructure, R&D, its workforce, and its supply chain to deliver today and tomorrow’s national security needs.

With the most diversified portfolio of capabilities in missile defense, Northrop Grumman brings trusted, ready-now, next-gen technologies for end-to-end missile defeat. The company is a proven integrator who delivers this technology with speed, through advanced software development, new hardware design, material science and manufacturing at scale.

Northrop Grumman is a leading global aerospace and defense technology company. Our pioneering solutions equip our customers with the capabilities they need to connect and protect the world, and push the boundaries of human exploration across the universe. Driven by a shared purpose to solve our customers’ toughest problems, our employees define possible every day.